Canoe Construction - How Cedar Canvas Canoes are Made

The cedar canvas canoe represents the European adaptation of the bark canoe built and used by the native people. As suitable bark became more difficult to obtain and to facilitate industrial production, canvas was substituted for the bark and rendered waterproof by the application of oil, tar or paint.

The cedar canvas canoe represents the European adaptation of the bark canoe built and used by the native people. As suitable bark became more difficult to obtain and to facilitate industrial production, canvas was substituted for the bark and rendered waterproof by the application of oil, tar or paint.

Cedar canvas canoes have a long and romantic history in Canada and the north-eastern United States where they have been built in small shops and large factories for about 125 years. Many people think of them as 'old fashioned' canoes and are surprised to learn that they are still being built today. In fact the methods of manufacture have changed little in the past 125 years, ensuring the same high aesthetic qualities and superior handling characteristics of the classic canvas covered canoes.

Before a cedar canvas canoe can be built, a form has to be constructed. The canoes are built directly onto this form so that it determines the shape of the canoe hull. Building the form is an exacting and lengthy process that can take 200 - 300 hours. However, once the form is complete, a large number of canoes can be built on it, one at a time.

Before a cedar canvas canoe can be built, a form has to be constructed. The canoes are built directly onto this form so that it determines the shape of the canoe hull. Building the form is an exacting and lengthy process that can take 200 - 300 hours. However, once the form is complete, a large number of canoes can be built on it, one at a time.

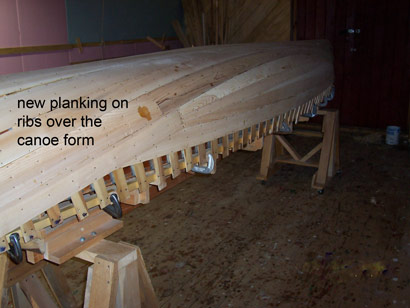

The first step in the construction of a new canoe is to clamp the inwales and the stem pieces to the form. Next the cedar ribs are steamed and bent, one at a time, over the form and nailed to the inwales. This forms the skeletal shape of the canoe. The red or white cedar planking is then applied over the ribs and secured to each rib with 3 or 4 brass tacks. Metal bands on the form clinch each tack into the inside surface of the ribs to create a secure connection between the planks and the ribs. Approximately 2000 tacks are used in a typical 16 foot canoe.

When the planking is nearly complete, the canoe is removed from the form. The shear planking is then completed and the ends of the canoe are closed up.The canoe is then sanded and cleaned inside and given at least 4 coats of marine spar varnish. Decks, seats and thwarts are added and the canoe is ready for canvassing.

When the planking is nearly complete, the canoe is removed from the form. The shear planking is then completed and the ends of the canoe are closed up.The canoe is then sanded and cleaned inside and given at least 4 coats of marine spar varnish. Decks, seats and thwarts are added and the canoe is ready for canvassing.

The canvas is folded lengthwise to form a trough and then stretched until taut. The canoe is placed into the trough and the canvas is attached at the top of each rib with brass tacks or stainless steel staples. At the ends of the canoe the canvas is carefully slit and pulled, one side at a time, around the stem and fastened. The canvas is then 'filled' with a product that fills the weave and makes a smooth, solid base for the finishing paint.

After the filler has cured, the outwales are added and the canoe is then given at least three coats of marine enamel. Finally, the ends of the canoe are finished off with the installation of brass stem bands. The time required to build a canoe varies with the size and the degree of finish and can range from about 80 to 200 hours.